In modern electrical grids, overhead bare conductors made from aluminum are widely used due to their light weight, cost-effectiveness, and conductivity. The three primary types are:

AAC – All-Aluminum Conductor

AAAC – All-Aluminum Alloy Conductor

ACSR – Aluminum Conductor with Steel Reinforcement

These conductors carry power from generating stations to end users, with aluminum’s 99.7 % purity (in AAC) being a key factor.

A pioneer in the cable industry SINCE 1979 - Shenxing Cable

Shenxing Group has more than 45 years of experience in cable production. Our strength lies in the development and manufacture of cable products according to customer specifications. At Shenxing, we see ourselves as a manufacturer and service provider - in the sense of a true partnership and customer-oriented work.

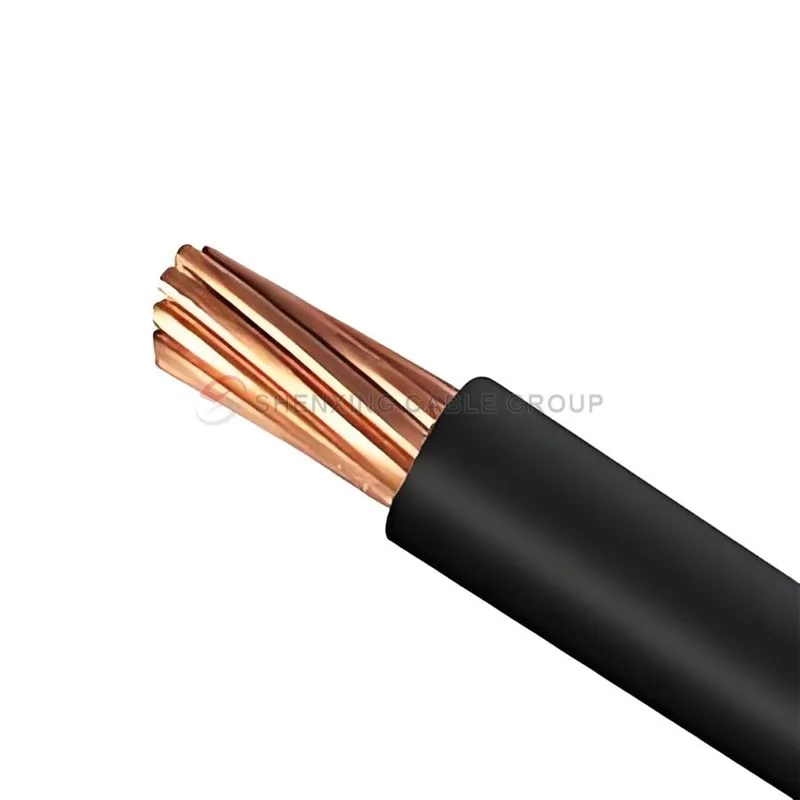

All Aluminum Conductor Overhead Cable AAC

Material Composition

What Makes Each Conductor Unique?

AAC consists solely of high-purity aluminum wires (1350‑H19 grade).

AAAC is built from aluminum alloy wires (often 6201), offering enhanced mechanical strength and corrosion resistance compared to pure aluminum.

ACSR combines outer aluminum strands with a galvanized steel core, achieving greater tensile strength and reduced sag thanks to steel’s mechanical support.

Corrosion Resistance & Durability

How They Stand Up to the Elements

Pure or alloy aluminum—AAC and AAAC—offers excellent natural corrosion resistance. ACSR, however, is more susceptible to rust due to its steel core, unless the steel is galvanized or coated.

All Aluminum Alloy Conductor-AAAC Cable

Performance Characteristics

Tensile Strength vs. Electrical Capacity

ACSR excels in mechanical performance: its steel core supports heavier loads, allows longer spans, and minimizes sag—ideal for heavy-duty overhead lines.

AAAC, though lacking steel reinforcement, provides superior corrosion resistance compared to ACSR and better strength than AAC, making it suitable for moderate span installations.

AAC is the lightest and easiest to install but offers the least mechanical strength—often sufficient for shorter, less demanding runs.

Choosing the Right Conductor

Key Factors & Applications

ACSR is the go-to for applications requiring high tensile strength, such as long spans, windy or storm-prone areas, and heavy-load scenarios.

AAAC offers a balanced option with improved corrosion resistance, decent strength, and lighter weight—ideal for overhead distribution systems.

AAC is best for lighter-duty lines where installation ease and low cost are priorities, and mechanical stress is minimal.

Aluminum Conductor with Steel Reinforcement

Which Conductor Should You Choose?

Selection depends on balancing factors like span length, mechanical load, corrosion environment, lifespan, and budget:

ACSR: Top mechanical performance and low sag, best for high-load, long-span, or challenging environments.

AAAC: Excellent corrosion resistance, moderate strength—ideal for typical distribution lines.

AAC: Lightweight and cost-effective, suited for short spans and light-duty installations.

Choosing the appropriate conductor ensures reliability, cost efficiency, and long-term performance in overhead power systems.

Whichever cable you choose, those are the top standard cables for utility power lines nationwide. Shenxing is a leading seller of ACSR, AAC, and AAAC cables on the market, with some of the best prices on high-quality products. Aluminum transmission and distribution cables have been some of the most popular cables in our product range.

A pioneer in the cable industry SINCE 1979 - Shenxing Cable

Shenxing Group has more than 45 years of experience in cable production. Our strength lies in the development and manufacture of cable products according to customer specifications. At Shenxing, we see ourselves as a manufacturer and service provider - in the sense of a true partnership and customer-oriented work.

Widely used in machinery manufacturing, oil exploration, national defense andmilitary, electrical equipment, fire engineering, construction, metallurgy,farmland irrigation and other industries.